Products

- Circular Connectors & Cable Assemblies

- D-Sub Connectors

- IP67 D-Sub Connectors

- D-Sub Backshells

- Micro-D Connectors & Cable Assemblies

- Power-D & Combo Mixed Connectors

- Push Pull Connectors

- D-Sub & Micro D Hardware

- Modular RJ45 Connectors

- USB Connectors

- D-Sub Adapters & Gender Changers

- SCSI .085"/.050"

- .050 Ribbon

- Headers & Receptacles

- Bayonet Connectors

Connectors in the Energy Sector

Here power and signal connectors for electronics are essential for monitoring and managing energy systems, both for regional networks and small, standalone installations.

Yet selecting standard varieties of connectors may not be appropriate for many energy sector requirements, especially those in harsh outdoor or industrial environments. The choice of IP-ratings, materials, mating interfaces, housings, and shielding may vary based on where a product is deployed.

Further, because energy projects are often stationed in remote locations, fail-proof durability and higher-quality electrical performance will reduce cost-intensive maintenance calls in the field.

This post recommends the best connectors for signal and power for energy applications.

Connector Considerations for Energy Applications

Geographic setting

The energy sector encompasses many very different geographic settings: an offshore oil rig or a desert solar array or a hydroelectric dam. To make the best selection for components in harsh environments, it is important to know the water and solid particle exposure the deployment setting will likely have.

Some examples where location is a factor in selecting connectors:

- Marine environments — Connectors deployed on, say, an offshore wind farm, gas exploration platform, or tidal and wave system will require at minimum IP64 ratings to ensure they can withstand incoming ocean waves without ingress of moisture. A prudent option is to use IP67 rated connectors to ensure the device can withstand submersion in shallow water. Very rugged marine electronics will need IP68 rated connectors to ensure the device can be retrieved from deeper water without damage.

- Industrial settings — Not all energy infrastructure is outdoors. An oil refinery or coal plant may bring nearby hazards such as thermal extremes, dust particles, or stray chemicals, as well as possible mechanical shocks or stressors.

Depending on the type of equipment being used in an industrial environment, IP65 or higher rated connectors are recommended. While these connectors may need to withstand water spray at various pressures, they are not likely to become submerged.

- Extreme heat — Sensors and controls in solar energy systems require connectors that can endure the relentless heat and UV radiation typical of solar farms. Dry conditions, such as deserts, would need seals to prevent ingress of particles.

- · Cold, snow, and ice — Besides an appropriate IP rating against weather, robust EMI/RFI shielding is required to protect signal integrity, especially where icy conditions may be accompanied by high winds and dust that can generate static electricity. Also consider locking mechanisms and substantial housing that can resist thermal expansion.

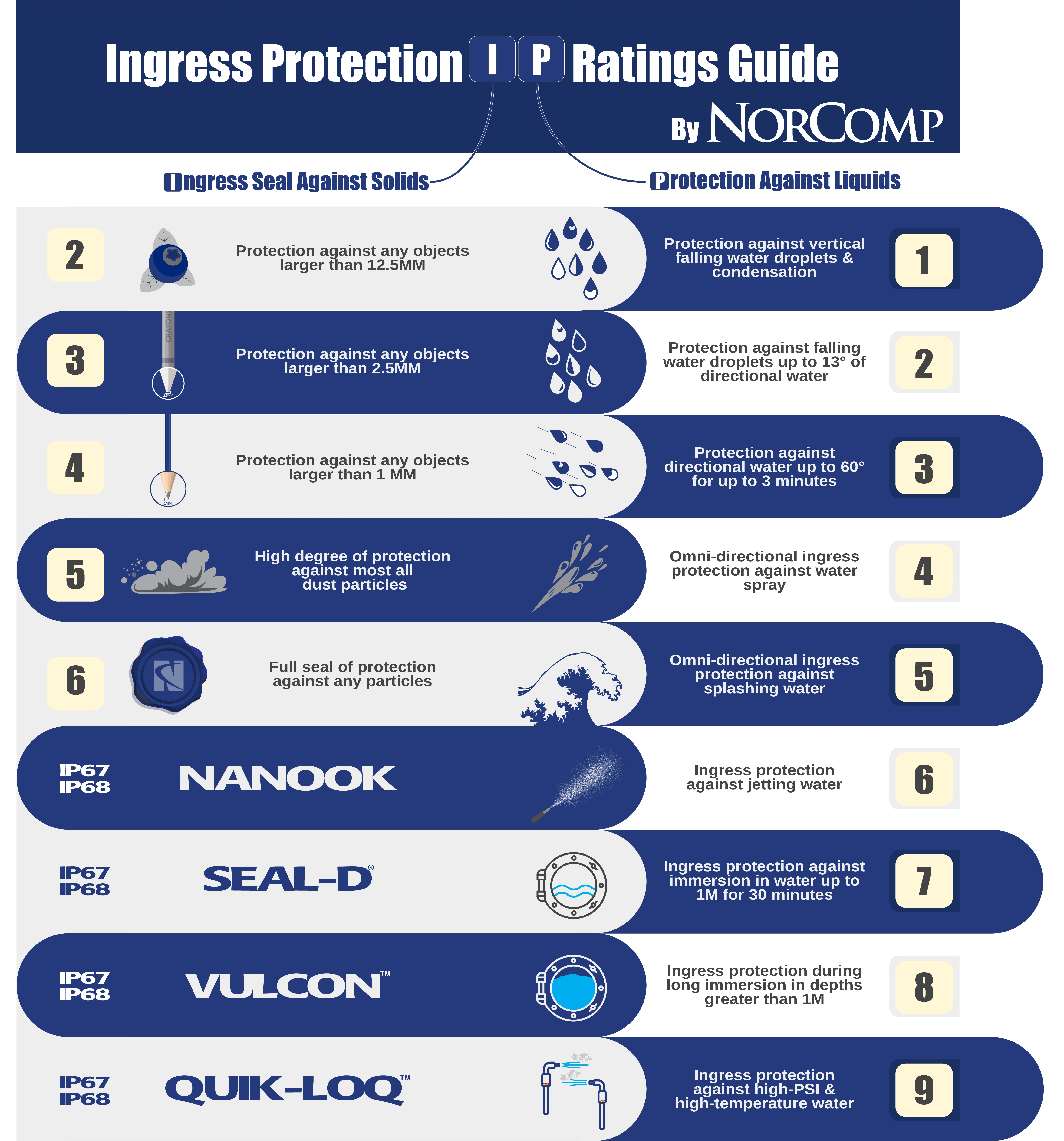

Ingress Protection

The following graphic indicates the leading NorComp connector brands that offer levels of ingress protection (IP) according to standardized ratings.

The first digit in the IP rating represents the particle ingress resistance — for instance, 6. The second digit indicates moisture protection, 7, giving the overall component rating of IP67. In general, larger numbers in the code reflect greater protection against solid debris and liquid contaminants.

The connector housing, insulator, contact style, and materials all work together to determine the IP rating of the component. The designer’s responsibility is to determine the IP rating required for a particular deployment environment.

Electrical performance

Even if they are not handling the high-voltage loads of the grid, connectors supporting devices and equipment still require stable power supply. For continuous uninterrupted operations, their designs need to mitigate risks such as power surges or voltage drops.

The proliferation of sensors and control systems in smart energy grids has elevated the need for connectors capable of handling high-density data transmissions without sacrificing signal integrity.

Durability

The vibration and dynamic forces exerted on wind turbine controls require connectors that maintain a reliable connection over time.

Secure connect-disconnect features reduce downtime and enhance the safety of maintenance personnel who often operate in challenging conditions. Such design considerations can prevent accidents.

Both the longevity of the component and the stability of the connection mean fewer maintenance costs serving remote, hard-to-access energy installations.

The Leading Brands

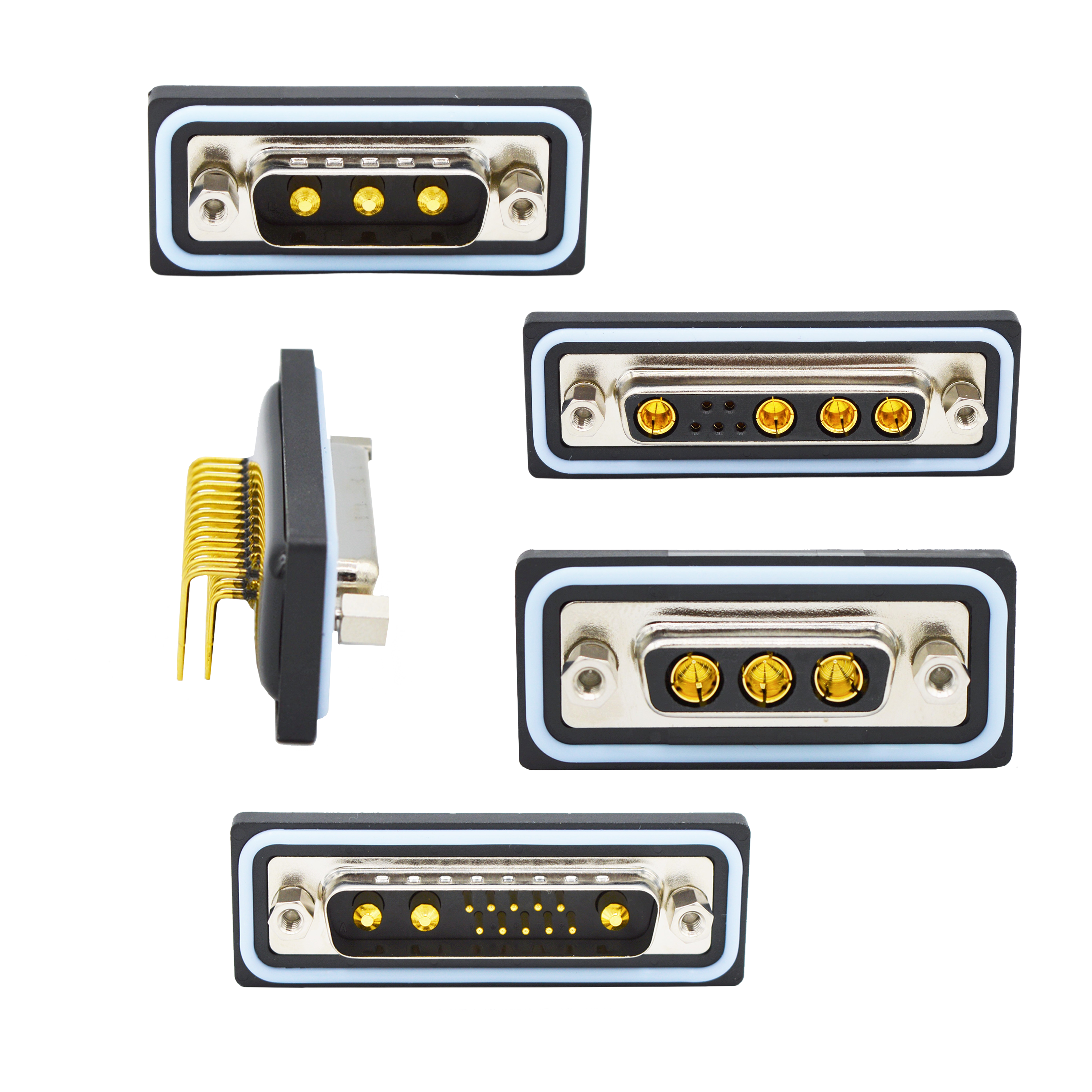

NorComp’s own lines of high-performance IP-rated interconnects fit the bill for many energy sector applications, with precision pin construction, stronger backshells, and waterproof seals:

NANOOK

NANOOK waterproof d-sub connectors offer an all-inclusive solution for a wide range of telecommunication and computer applications, and contain a flange for strong attachment. With many options delivering signals or power-and-signal, NANOOK can operate in an extreme range of temperature: -25°C to +85°C.

SEAL D®

Check out NorComp’s proprietary extra waterproof seal on the common d-sub style multi-pin connectors, SEAL D. Ideal data connectors to computers, sensors, and meters, SEAL-D are designed for applications that require protection from heavy spray or are exposed to short-term submersion.

[embed video]

VULCON

Corrosion-resistant and durable stainless-steel works best for the broadest range of energy sector applications. The VULCON stainless steel M12 connector shown above features metal housing and an overmolded right-angle cable assembly that protects against mechanical impact. This reinforced circular connector style supports M5/M8/M12 cables, and are widely used in sensor applications.

QUIK-LOQ™

The NorComp line of QUIK-LOQ™ Circular Push-Pull Connector systems are rugged, sealed connectors ideal for waterproof applications where quick connect and disconnect are required.

Count on Norcomp for the Highest Quality

In the control and monitoring of energy, connectors must be robust, compliant, and precise, providing uninterrupted operation and safety in some of the most demanding environments. Engineers have come to expect the best in mechanical and electrical reliability in connectors from NorComp.

For help selecting the best rugged connection for your specific application, see the brochure below or contact a helpful technical specialist.

Go Back