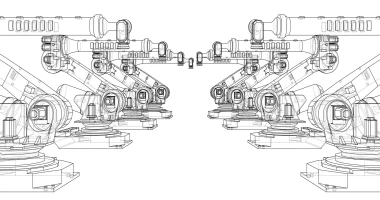

RoBOT & CONTROL TECHNOLOGY

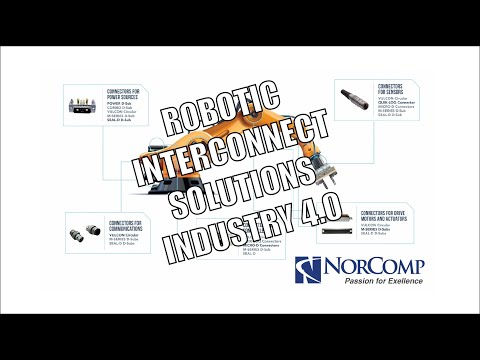

Industrial robotic devices are highly complex electro-mechanical machines that may contain multiple computers, dozens of sensors, hydraulic pumps, multiple motors and connections to a network. Also the technology trend is helping drive the need for reduced size, weight, and power consumption, as well as driving demands for increased connector throughput.

TWIST, SPIN, AND ROTATE

Robotic workers perform a ballet of movements that always need to hit their

mark. Don’t leave it up to chance—find connectors that can reliably hoist

parcels, navigate aisles, or turn on a dime.

ALWAYS SENSING SURROUNDINGS

Collision detection, object scans, torque, and pressure sensing. Robotic

devices have their own eyes and ears to continuously make split-second

decisions. Connectors play a key role in maintaining sensor uptime.

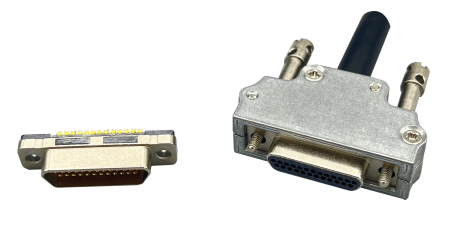

NON-STOP DATA TRANSMISSION

Industrial robots constantly send and receive signals to do their

jobs properly. Connectors with robust coupling mechanisms ensure

communication lines are always open.

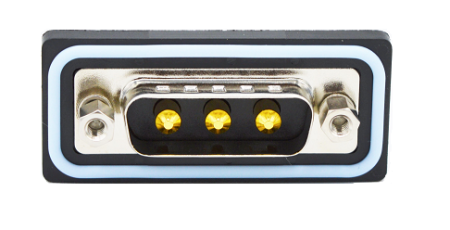

SUPER-RUGGED FOR INDUSTRIAL FACILITIES

Factory floors swirl with fumes, welding sparks, corrosive substances,

dust, and more. Rugged IP environmental sealing defends systems against

blisteringly harsh conditions.

SMALL FOOTPRINTS

Industrial robots can house dozens of sensors in a compact footprint.

More sensors and controllers crowd together, reducing space for

oversized components. Miniaturized interconnects pack in the

performance in a much smaller package size.